Shung Fong Organic Fertilizer—Break Through the Succession Dilemma and Move Towards Refined Agriculture

Background

Shung Fong Organic Fertilizer Co. is a pioneer in the manufacturing industry of organic fertilizers in Taiwan. The company recycles and reuses food and plant waste residues plus agricultural and organic animal resources based on the concept of natural organic, energy-saving, and carbon-reducing environmental protection.

Challenge

Taiwan is facing problems such as an aging population and lack of labor caused by a declining birth rate. In the past, traditional agricultural production processes relied on the master worker’s experience to adjust formulas and parameters. When the master-workers retire, it is always a question of whether they bestow all their wisdom and expertise making the products. In addition, the production environment of organic fertilizers is poor and has peculiar smells. Many young people are reluctant to work in this environment, and managers have to face the problem of retirement and the continuity of their master-workers.

Solution

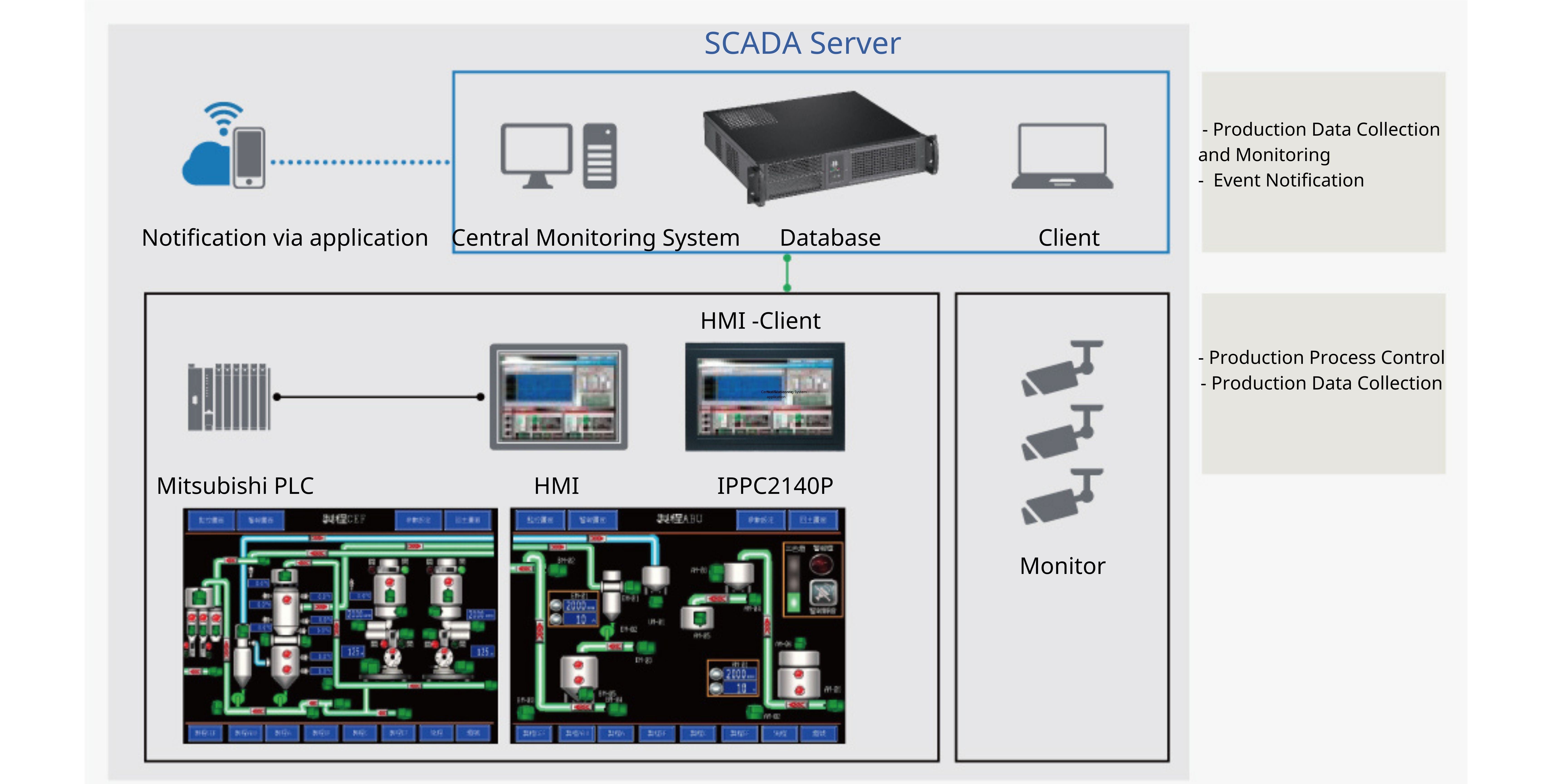

- HMI: IPPC2140P

Central monitoring system workstation computer:NexBox-Q170-2U

NexAIoT’s Intelligent Industry 4.0 planning consultant team has complete professional knowledge and technology and possesses a wealth of planning and implementation experience. Our team is skilled in assisting traditional agriculture in achieving automated production change.

The consultant team assisted in the planning and implementing of on-site process design and the automatic control system. The process design is divided into A feed, B mixing, C granulation, D drying, E cooling, F packaging, using NexAIoT 21.5" multi-touch screen—IPPC 2140P, a metal body with an aluminum frame, meets the IP66 waterproof and dustproof rating and has wide temperature characteristics. It is suitable for a harsh on-site environment for production data collection (temperature, material level, motor overload protection), on-site setting process parameters, display equipment, and process operating status report (electricity, wind speed, motor rpm, current, etc.)

The process production data collection can also be uploaded to the office's central monitoring system. Through TCP/IP, NexBox's Q170-2U3 workstation computer will provide a multitude of critical data elements. Reporting includes status analysis and query, event analysis, and warning functions such as fire alarms, motor errors. Managers can get the notification for immediate processing via the Line application.

Results and Benefits

1. 1.The owner employed the most suitable production environment parameter through extensive on-site production data collection and analysis. This act helped improve product quality, develop new products, and reduce machine maintenance time and cost through predictive maintenance and energy-saving. Managers could make real-time decisions and emergency responses remotely through the central monitoring system's information.

2. The alert system delivered event notifications on the manager's social media in real-time and reduced industrial safety incidents.

3.By establishing automation and SCADA systems, all production status and data can be seen through the system interface. The remote on-site monitoring and analysis successfully turned the crisis into an opportunity. The solution solved the problem of the retirement of master-workers and the lack of young people willing to enter the industry.

[Case Study] Organic Fertilizer