Lenovo I4.0 & iRPA Integration Project

Project Name

Lenovo I4.0 & iRPA Integration Project

Project Begins

2018/9

Project Ends

2019,still in progress

NexAIoT Contact

Jeffrey Chen Send an Email

Backgound

Lenovo Group is an international technology company established in China with operations in 180 markets. Lenovo focuses on global development and has established an industry-leading model of diverse corporate culture and operating models, serving more than 1 billion users worldwide. As a trusted leader of global technology companies, Lenovo helps customers to grasp the technology of tomorrow and transform the world today.

As the world's leading ICT technology company, Lenovo adheres to the concept of "wisdom, for every possibility", and provides users and the entire industry with smart terminals that integrate applications, services, and the best experience, as well as robust cloud infrastructure and industry wisdom solutions Program.

Lenovo is the world's leading manufacturer of smart devices; it provides hundreds of millions of intelligent terminal devices, including computers, tablets, and smartphones, to global users every year. Lenovo's PC sales volume ranked first in the world in 2018. As the world's top supplier of enterprise digitization and smart solutions, Lenovo actively promotes the development of "equipment + cloud" and "infrastructure + cloud" in all industries, as well as the implementation of smart solutions.

Facing the opportunity of a new round of intelligent transformation of the industry, Lenovo puts forward a strategy of smart transformation, focusing on the three directions of Smart IoT, Smart Infrastructure, and Smart Verticals to become the industry leader and enabler of intelligent transformation.

At present, Lenovo owns four business groups: Smart Device Group (IDG), Data Center Business Group (DCG), Lenovo Venture Capital Group (LCIG), and Data Smart Business Group (DIBG). There are approximately 57,000 employees worldwide, with businesses covering more than 180 countries and regions. In the 2018/2019 fiscal year, Lenovo's overall turnover reached 51 billion U.S. dollars (340 billion yuan).

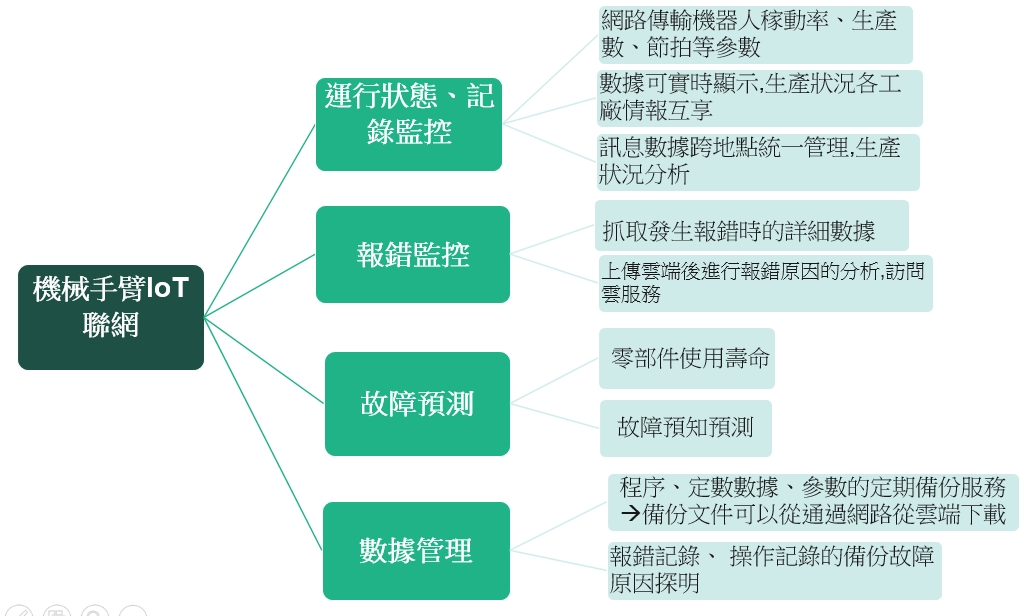

Challenges

Introduce IoT equipment and systems to implement the robot's failure prediction, error monitoring, status and record monitoring, and data management functions.

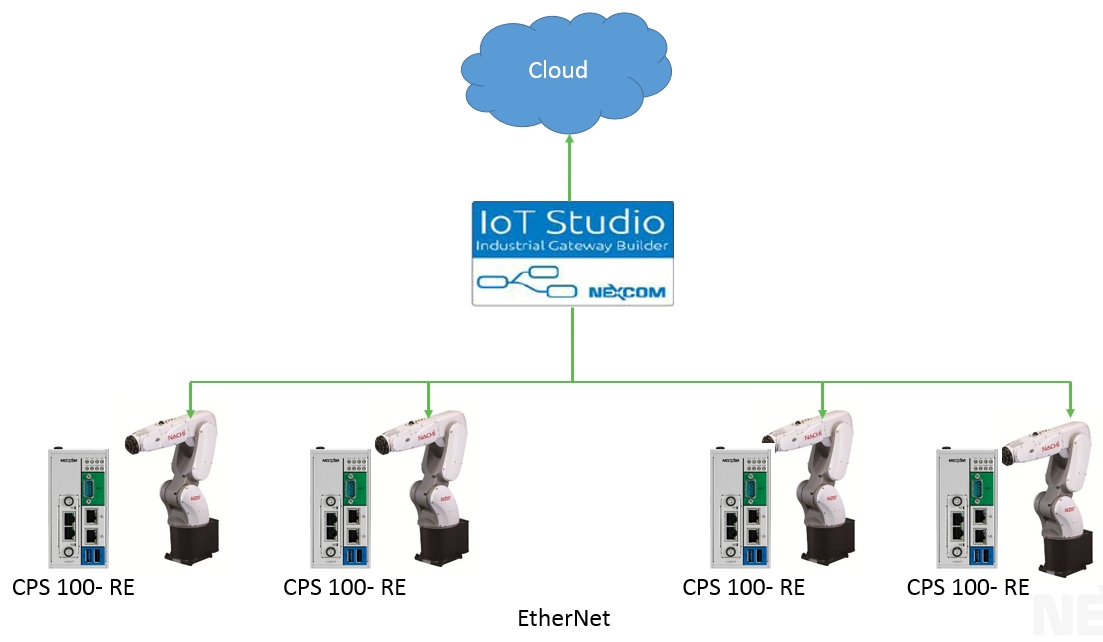

Solution System Architecture Description

Industrial IoT Remote Gateway

Through Modbus TCP/RTU, OPC UA, and IoT studio, centralized and decentralized field data can be easily deployed to complete automated processes. Equipped with an accessible live bus, users retrieve not only real-time monitoring data but also extract essential information about the customized process.

Error Monitoring

By collecting or accumulating information from the robot, it is possible to monitor not only the operating status, error occurrence status, and welding quality, but also the long-term changes in the current, speed, life, and remaining life of the robot. The information collection method can be used after collection and analysis through the protocol opened by the robotic arm.

Results and Benefits

The complete AE technical service team of Chongqing NexGOL provides mature and stable total automated production line design and deployment, conducts various production data collection, storage, and management solutions, as well as closely integrates with the customer’s upper management system to manage equipment.NexGOL’s service brings the following benefits to customers:

1.After the motherboard is put on the shelf, it will be automatically transported. The specific motherboard will be selected according to the instructions of the Lenovo kitting system, and the work will be automatically launched. This process is for all the motherboards produced by Lenovo, with 80 different material numbers. There are seven different sizes after the integration of specifications.

2.Copy the existing four main types of motion, manually load the conveyor according to the instructions of the kitting system. The conveyor records and transmit the loading information. RGB vision performs automatic selection of the motherboard base on the Lenovo kitting system. The six-axis robots replace the laborers to perform positioning and grabbing tasks.

3.Use the direct collection of equipment data and implementation of data management to eliminate the manual records and production line chaos caused by the unexpected shutdown and ensure the authenticity and availability of data.

4.Based on failure prediction and analysis, managers are alerted to perform preventive maintenance or scheduled replacement of parts and components, which greatly reduces the impact on production capacity due to sudden failures.

5.According to the error reporting system to collect the causes for the shutdown, perform the FA (failure analysis) or CA (cause analysis) control and formulate a rectification plan.

6. Real-time operation monitoring accurately grasps the utilization and capacity of production equipment, and you can instantly comprehend the operation status of each workshop and even the production line of various branches base on the uploaded data.