ANKO Food Machine Company - Journey of The Digital Transformation

Background

ANKO Food Machine Company predominantly sells to overseas markets. Its high-quality, multipurpose filling and forming machine, also known as a dumpling making machine, is its top-selling product. Other products include shumai, wonton, steamed bun, tapioca pearl, egg roll, and scallion pancake production machines. With many years of food machinery manufacturer experience, ANKO Food Machine has reached customers around the world.

In order to better understand clients’ usage behaviors during food production, develop the quickest servicing plan possible, and increase production capacity while reducing waste, ANKO Food Machine has gradually turned towards digitalizing its food machines, with the ultimate goals of improving predictive maintenance and client production yields.

Challenges

1. During production, human operational error causes unexpected failures. ANKO Food Machine needs a system that can monitor any damage to food machinery components.

2. ANKO Food Machine would like to reduce waste produced by its machines, so it first needs to understand customer usage behaviors.

3. ANKO Food Machine anticipates transforming its operations to smart machinery, as well as provide and develop services to remotely monitor its machines.

4. Implement IoT equipment and systems to carry out predictive maintenance and keep operational maintenance records.

Solution

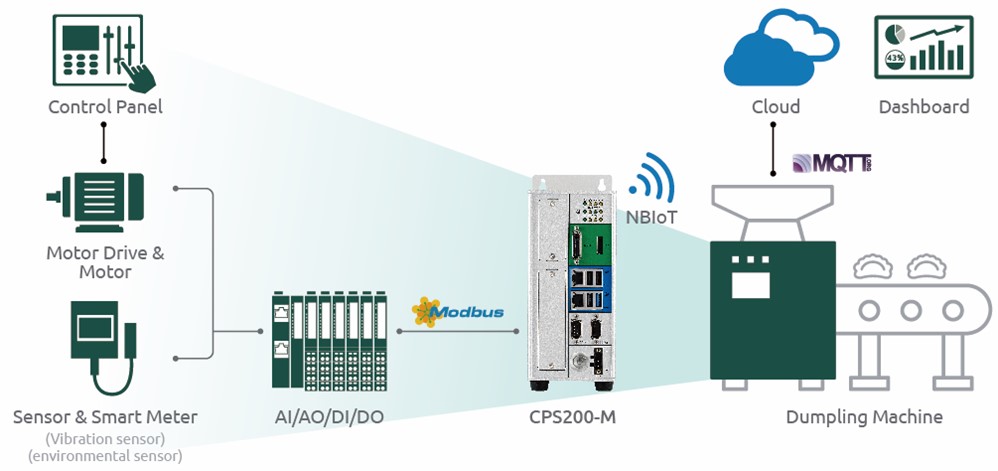

the CPS200 IoT gateway for remote monitoring

- Gateway: CPS200

- IoT Software: IoT Studio

NexAIoT recommended that ANKO Food Machine uses its CPS200 IoT Gateway with its internally developed and built-in HiveX IoT Studio. One of HiveX’s functions is to enable I/O modules to collect accelerometers’ vibration amplitudes so that users can find damaged parts. HiveX can also act as a server to store data regarding operations, abnormalities, and maintenance. With one click, it can easily complete three actions: data transfer, storage, and analysis.

Results

1. Motor speed determines both dumpling quality and shape. ANKO Food Machine’s dumpling making machine has five motorized axes that perform dough extrusion, auxiliary dough extrusion, filling extrusion, auxiliary filling extrusion, and dumpling formation. ANKO Food Machine has found the best operational combination for each different recipe, resulting in a more stable production process that produces 7000 dumplings per hour. Material waste has also decreased accordingly from 5% scrap rate to 4%, thus reducing eight tons of wasted raw materials every year.

2. In terms of maintenance, ANKO Food Machine ordinarily needed to send maintenance personnel on-site. However, because the epidemic has restricted activities abroad, yet ANKO Food Machine cannot cease services, ANKO Food Machine has installed accelerators on its dumpling machines, which detect vibration amplitudes, thus reducing machinery downtime.

3. Since installing CPS200, ANKO Food Machine has been able to better understand customer’s wear and tear conditions, reduce the number of repair visits, establish maintenance records, service overseas customers no matter what time zone they’re in, increase customer trust, and save ANKO Food Machine and its client's maintenance costs, all while attaining the end goal of complete conversion to smart machinery.

[Case study] ANKO Food Machine