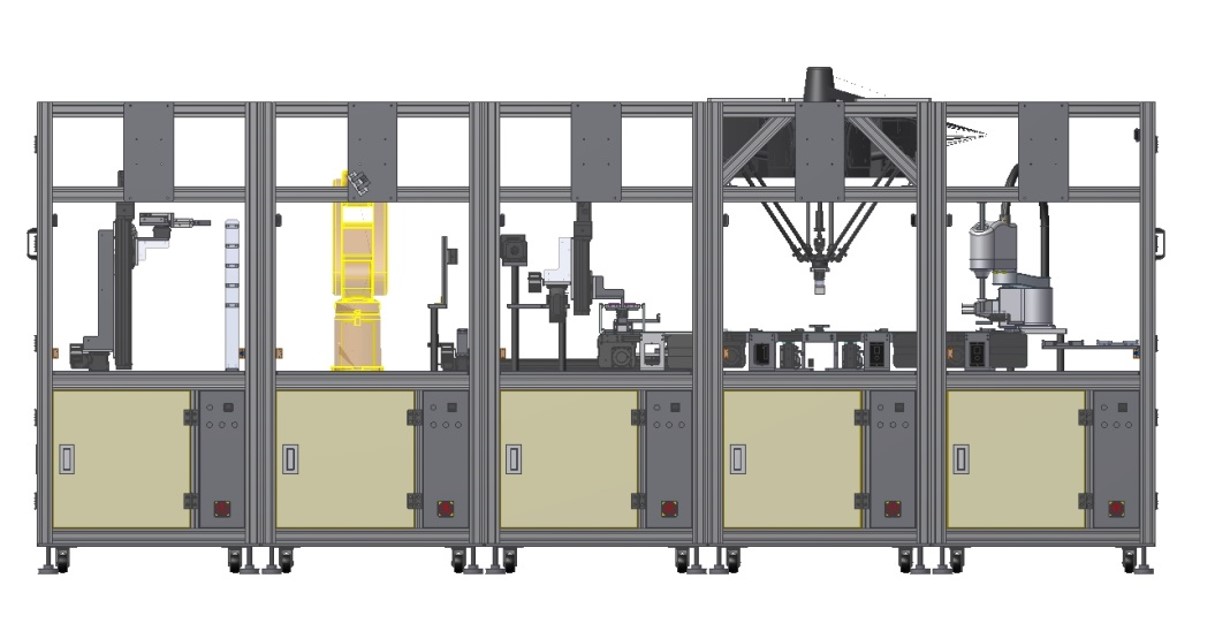

5-in-1 IoT Robot Production Line

Unmanned laser engraving cloud orders operation

This is a fully automated, unmanned production line that takes cloud order. It is suitable for small-quantity, diverse, and fast productions, and smart production lines or school teaching. After the customer places an order, the cloud ordering system automatically assigns work order to the robot production line, and the robots automatically complete the laser engraving production process of the ballpoint pen. The 6-axis vertical articulated robots, SCARA robots, Delta robots, and XYZ configuration machines used in this production line are controlled by the self-developed Robot Control System (RCS). RCS contains the robot controller––GRC and integrates third-party servo drives and safety electrical circuits that can support various brands and many types of robot arms.

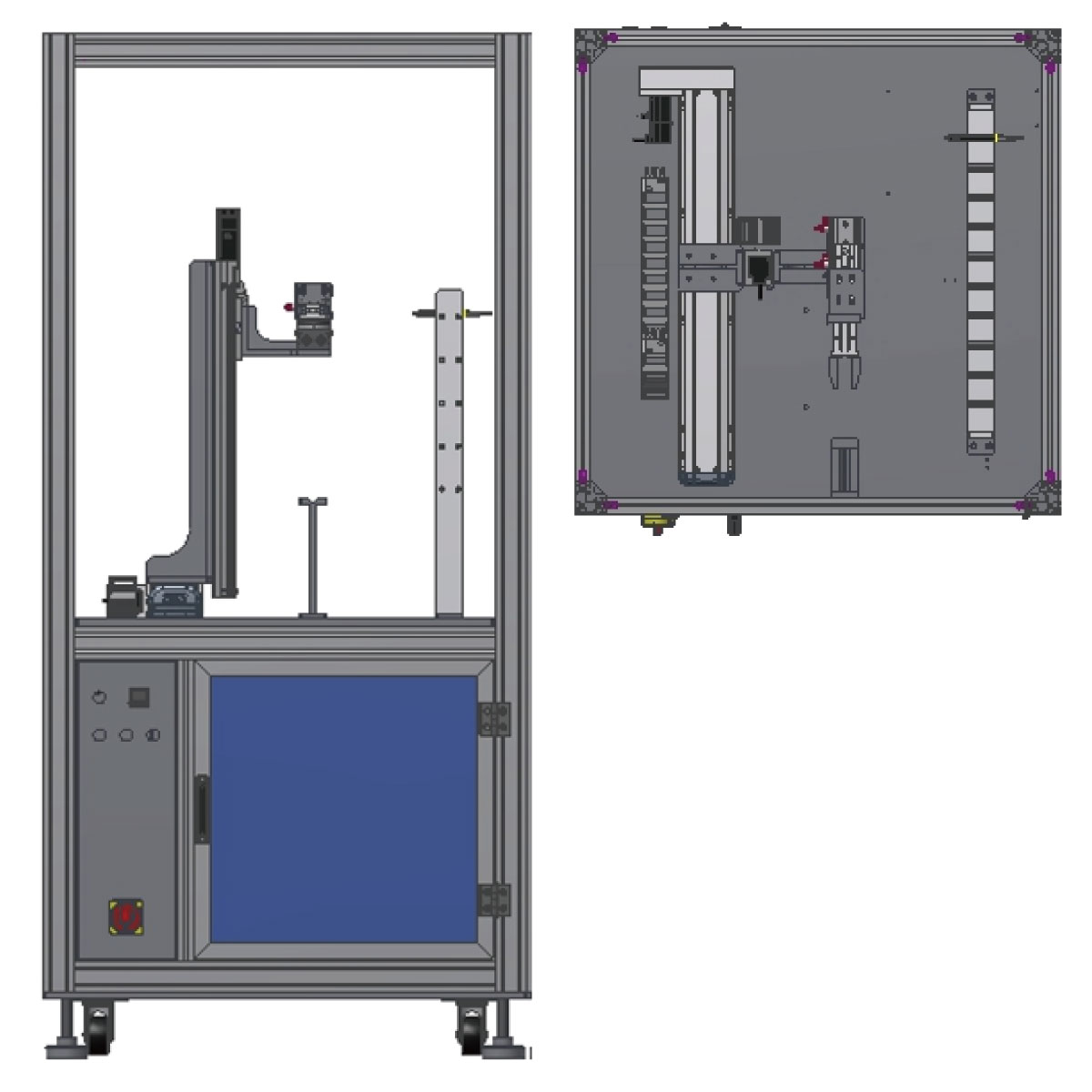

SCARA Tray Station

Main Missions

- Temporary reclaimer tray storage area

- Send the reclaimer tray to the conveyor belt and moved to the next station

- Recycle the reclaimer tray to the temporary storage area after its return

Fitted Robotic Arm

- Topstar TS650

Product Highlights

RCS200-4Axis

- Built-in RCB100-GRC controller

- Suitable robot types : SCARA 、Delta

- Motion control commands: point to point, straight line, arc

- Standard supported motors: Sanyo Denki, Tamagawa

- Supported motor encoder :Tamagawa,Nikon

- Support standard extended EtherCAT slaves

TP-100-1 & TP-100-VGA-JB

- 10.1" WXGA 1280 x 800 500 nits LED Panel

- Dual channels E-Stop button

- 3 channels Enabling switch

- Provide Junction box for simplify wiring

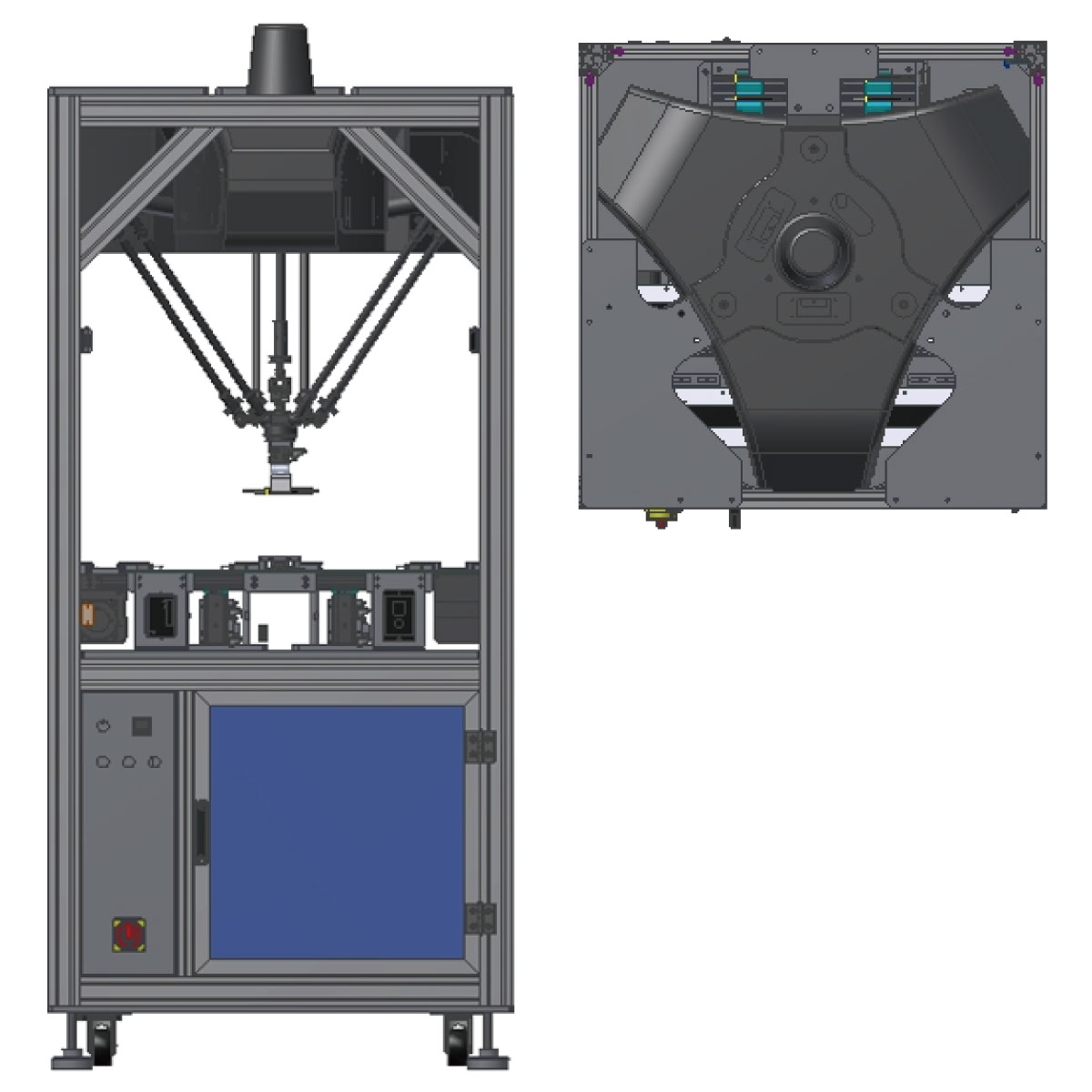

Delta Loading Station

Main Missions

- Take out the pen that needs customization from the feeding area

- Place the pen on the reclaimer tray and move to the next station

- Move the reclaimer tray after its return to the SCARA tray station

Fitted Robotic Arm

- Robot Phoenix BAT-580A

Product Highlight

RCS200-4Axis

- Built-in RCB100-GRC controller

- Suitable robot types: SCARA, Delta

- Motion control commands: point to point, straight line, arc

- Standard supported motors: Sanyo Denki, Tamagawa

- Supported motor encoder types:Tamagawa,Nikon

- Support standard extended EtherCAT slaves

TP-100-1 & TP-100-VGA-JB

- 10.1" WXGA 1280 x 800 500 nits LED Panel

- Dual channels E-Stop button

- 3 channels Enabling switch

- Provide Junction box for simplify wiring

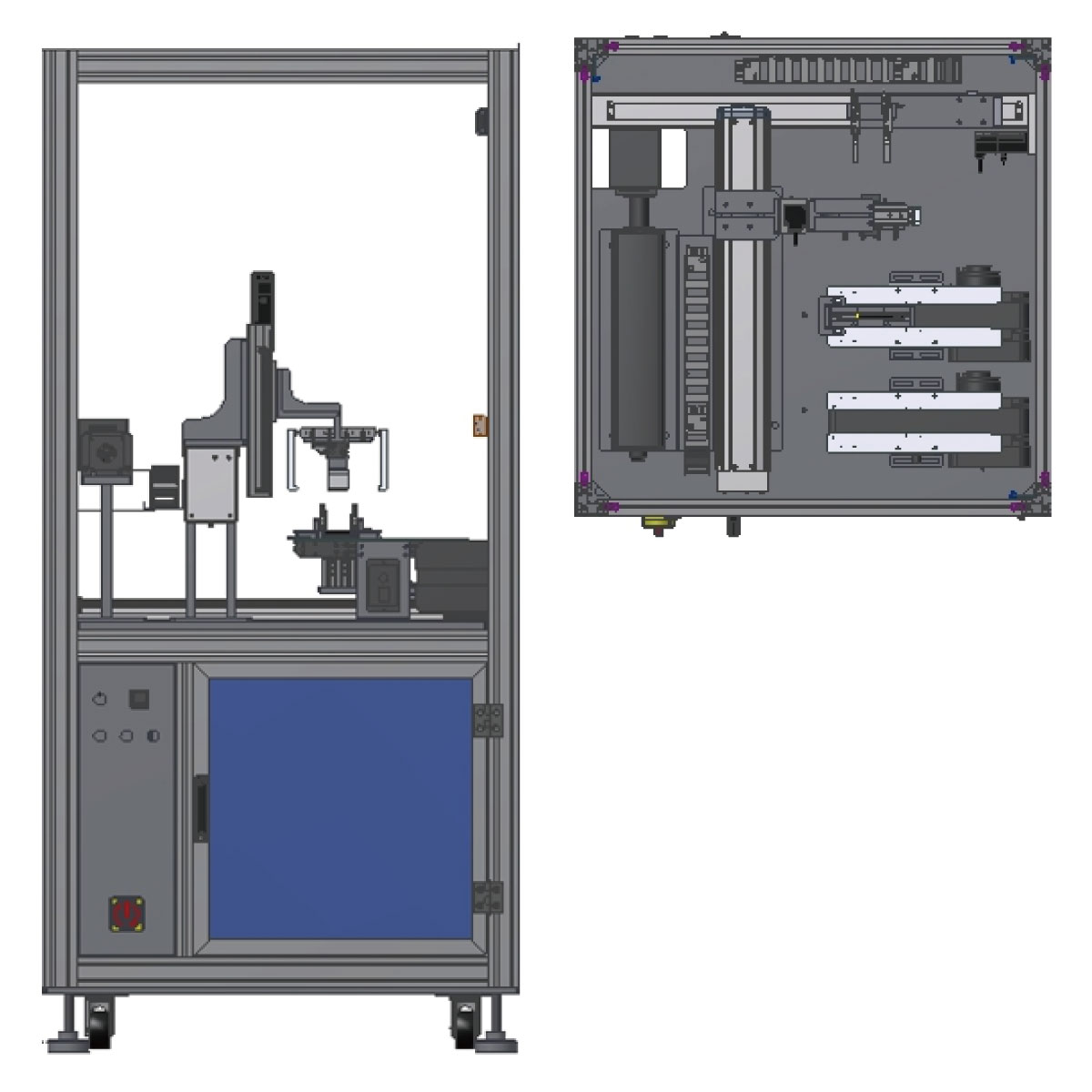

Laser Engraving Station

Main Missions

- Take out the pen that needs customization from the reclaimer tray

- Place the pen on the X-axis sliding table and move it to the laser engraving machine

- Recycle the reclaimer trays back to the Delta loading station

Fitted Hardware

- 1 XZ sliding table, 1 X sliding table, 1 NL-M20 laser engraving machine

Product Highlight

RCS200-4Axis

- Single axis no.: up to 16 axes

- Single axis control functions: PTP/Jog/Halt/Stop

- Support axes group no.: up to 2 groups

- Support axes group type: Cartesian coordinates machine (XY, XYZ table, XYZ& θ)

- Axes group control functions: PTP/linear/2D arc/3D arc

- NexCOBOT EtherCAT master, CoE and DC supported

- Provide windows APIs for user programming

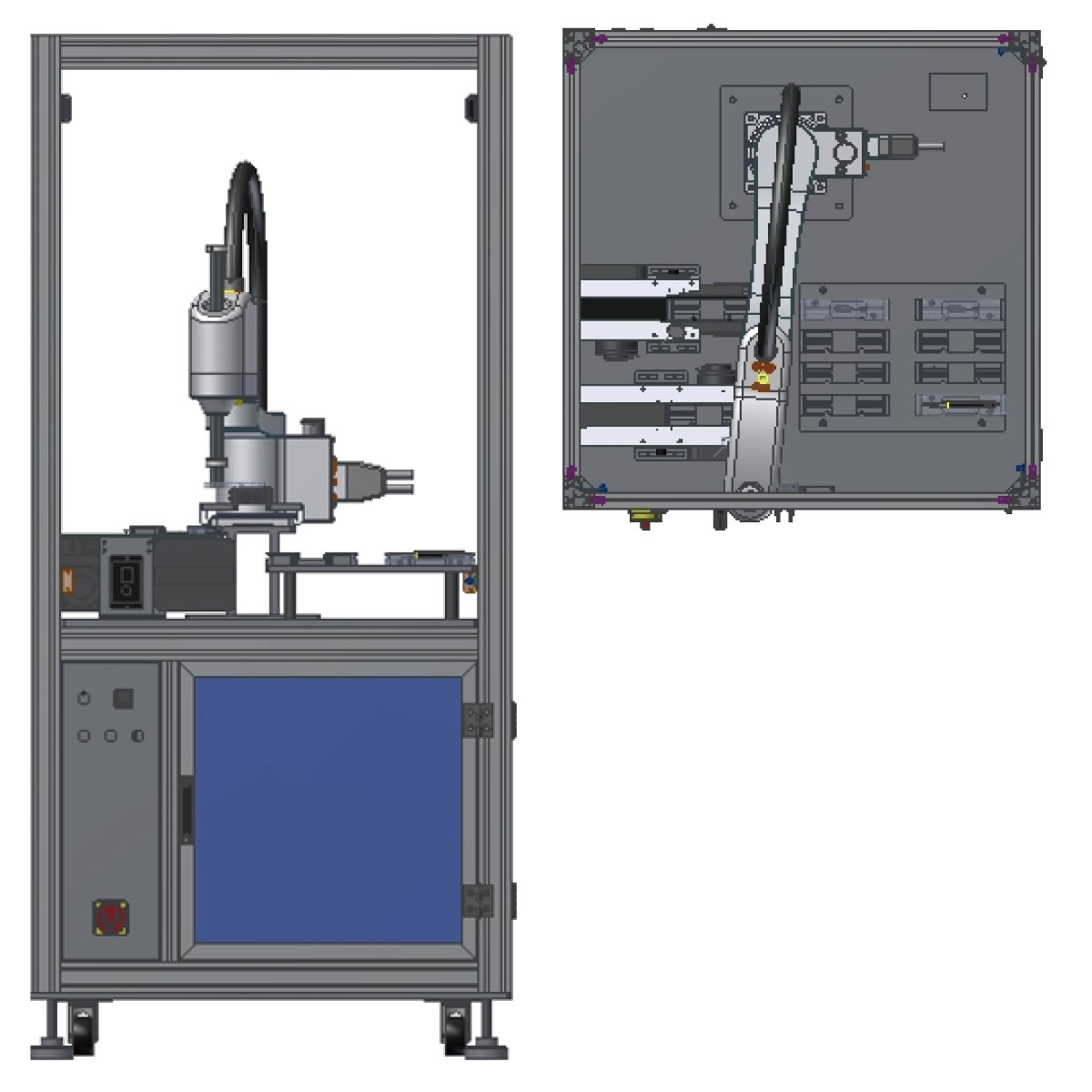

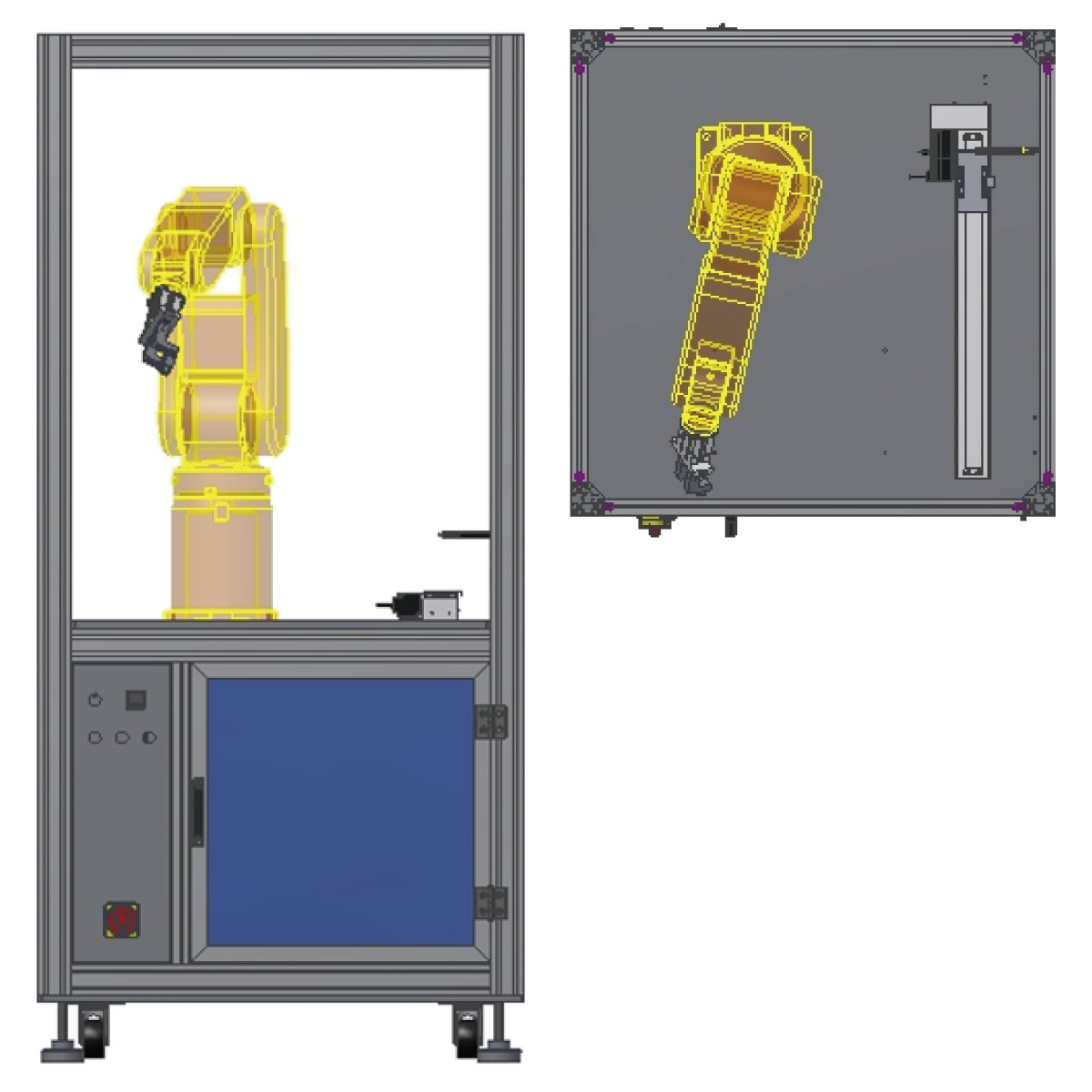

6-axis Receiving Station

Main Missions

- Take out the customized pen from the X slide table

- Place the pens in the storage station in order

Fitted Robotic Arm

- HIWIN RA605

Product Highlight

RCS200-6Axis

- Built-in RCB100-GRC controller

- Suitable robot type: Articulated 6-axis

- Motion control commands: point to point, straight line, arc

- Standard supported motors: Sanyo Denki, Tamagawa

- Supported motor encoder types: Tamagawa,Nikon

- Support standard extended EtherCAT slaves

TP-100-1 & TP-100-VGA-JB

- 10.1" WXGA 1280 x 800 500 nits LED Panel

- Dual channels E-Stop button

- 3 channels Enabling switch

- Provide Junction box for simplify wiring

Warehouse Discharge Station

Main Missions

- Deliver the pens from the warehouse to the discharge station

Fitted Hardware

- 1 XZ sliding table

Product Highlight

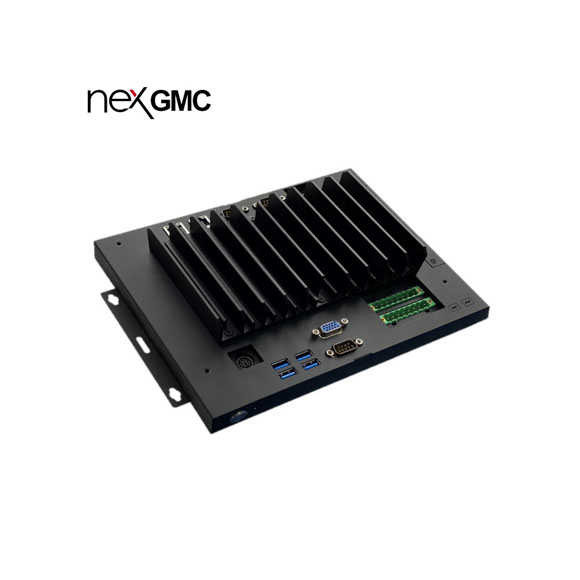

NET355-GMC16

- Single axis no.: up to 16 axes

- Single axis control functions: PTP/Jog/Halt/Stop

- Support axes group no.: up to 2 groups

- Support axes group type: Cartesian coordinates machine (XY, XYZ table, XYZ& θ)

- Axes group control functions: PTP/linear/2D arc/3D arc

- NexCOBOT EtherCAT master, CoE and DC supported

- Provide windows APIs for user programming