iAT2000 Starter Kit

iAT2000 Starter Kit Overview

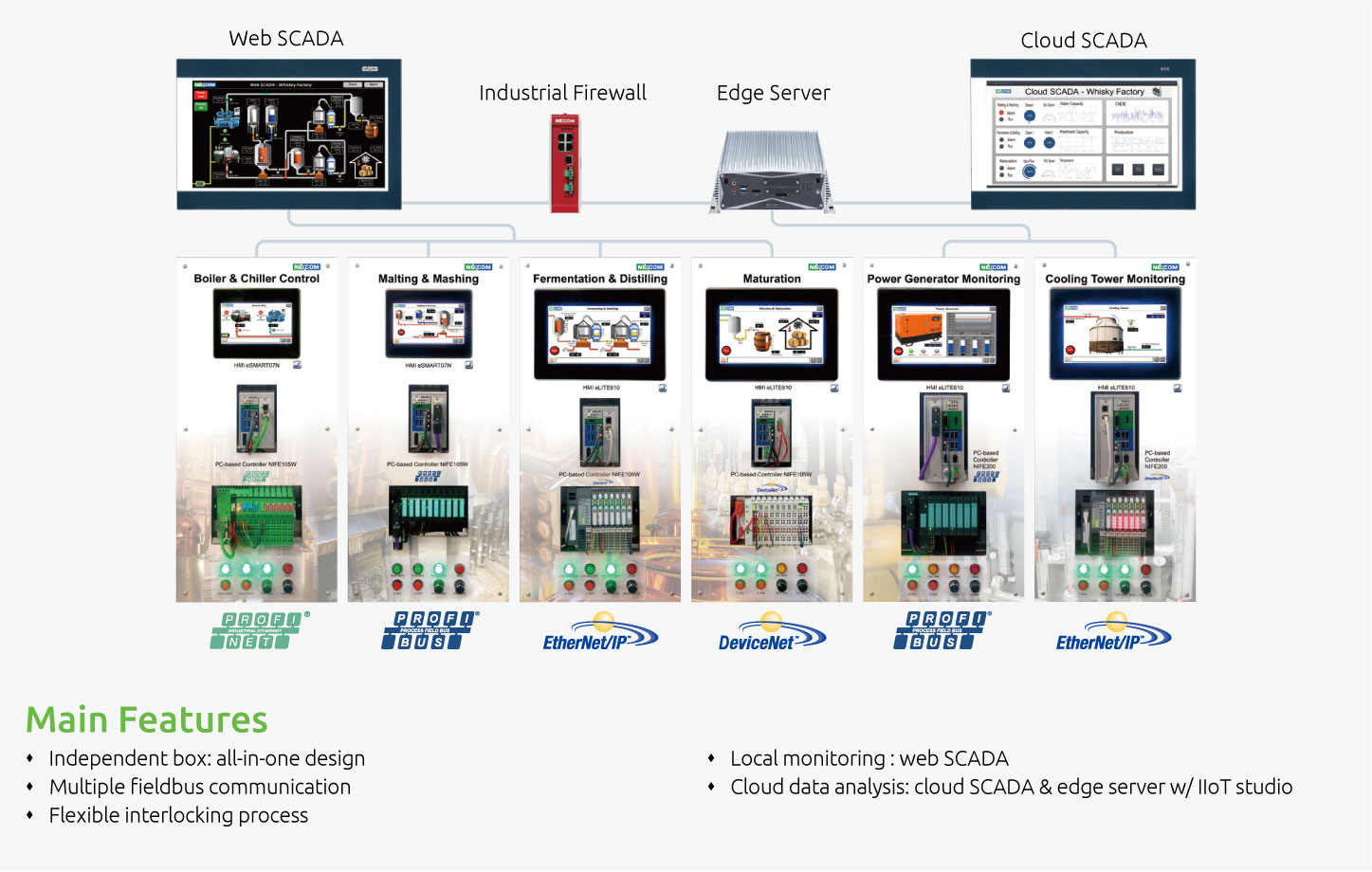

Are you looking for a system which integrates different brands of PLC or I/O devices and different protocols into SCADA, even to Cloud SCADA? Or are you looking for a solution that gives you flexible control schemes to factory process, and also meets the Industry 4.0 needs? The iAT2000 starter kit is the cloud-based automation control system which provides a visible, all-in-one solution to make factory process more efficient and productive. The architecture of iAT2000 is open but highly integrated. Each system components are utilized with NEXCOM technologies to achieve OT/IT convergence. With the comprehensive support lists of device I/O, PC-based controller, HMI, web SCADA to cloud SCADA, iAT2000 starter kit truly helps to users to save time and cost for OT/IT integration. Each independent pack installs one PC-based controller for controlling one particular factory process, and support interlocking mechanism for managing process flow. The process flow and status can be closely monitored or adjusted via web SCADA and cloud SCADA. iAT2000

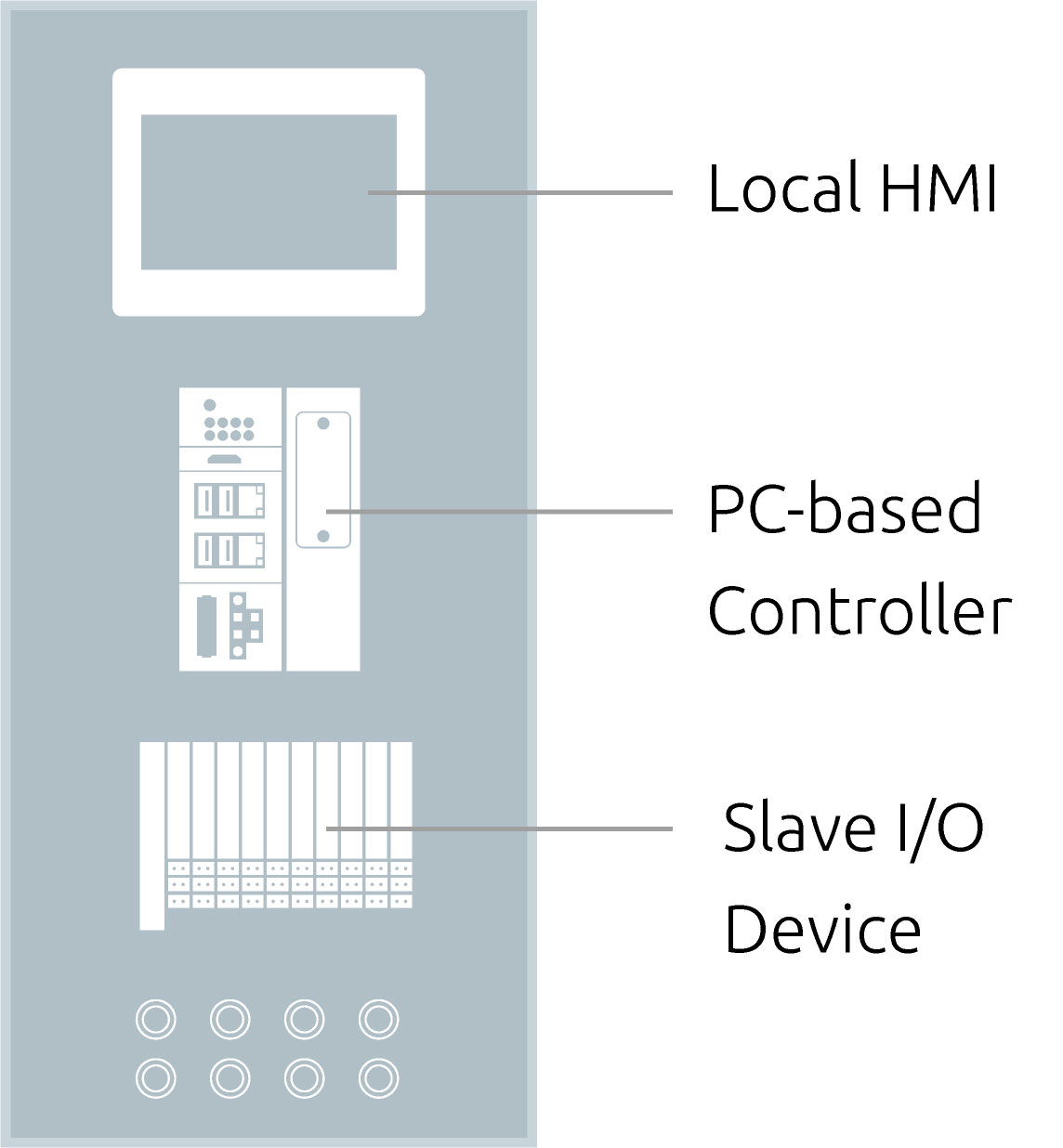

Independent Pack: All-in-One Design

The independent pack is the implementation of local HMI, PC-based controller, and device I/O. These three system components are the major cornerstones of the system infrastructure, which allows the users to do process control and visualizes field data on HMI. Each independent pack supports stand-alone operations, and equipped with basic I/O control units (LED, digital I/Os and analog I/Os). Users can use the independent to do practical field operations or simulations.

Major Features

iAT2000 starter kit is a complete package for users to explore the modern industry 4.0 architecture and gain the better understanding to the major components for the factory automation. This is an excellent package for education purpose, and moreover, the users can expand their own factory automation business by adapting iAT2000 starter kit.

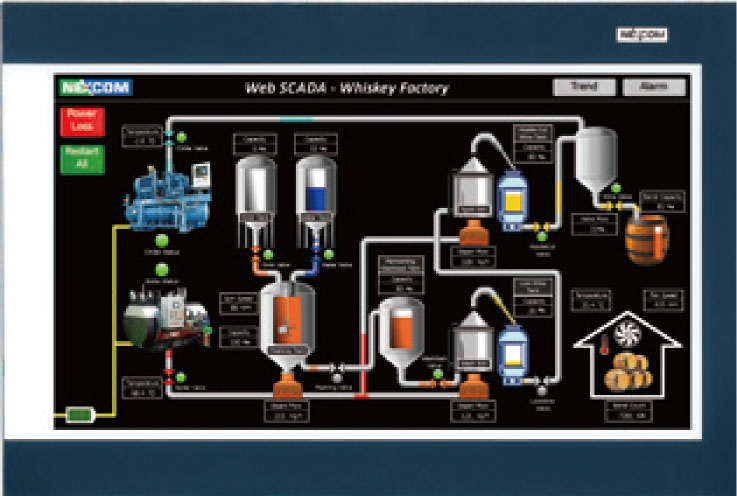

Local Monitoring: Web SCADA

Web SCADA provides single factory process overview and high level supervisory management to all Independent boxes in factory, and gives an efficient way to handle alarm events. Operator can monitor the entire factory process, and gives corresponding process commands. When an alarm is issued from the independent pack, the web SCADA will be immediately informed and indicates the failing points.

Cloud Data Analysis: Cloud SCADA & Edge Server w/ IIoT Studio

Cloud SCADA provides a broader overview for multiple factories, where the edge server receives and processes the data from the OT layer and transmits valuable information to the IT layer. In iAT2000 Start kit, the cloud SCADA indicates factory’s OEE value and productivity rate.

The Softlogic Inside PC-Based Controller

In each independent pack, there will be one PC-based controller responsible for data exchange. The softlogic inside PC-based controller enables the fieldbus communication and support IEC 61131-3 programming (IL/ST/LD/ FBD/SFC). The user can create dedicated programs for different factory process.

Visualizing the Process: Local HMI

Each independent pack in iAT2000 starter kit is equipped with local HMI for process monitoring. The local HMI comes with JMobile; a easy and powerful solution for creating HMI applications in a intuitive way. In iAT2000 starter kit, the user can view information and control process with local HMI/JMobile. The JMobile toolkit also supports a rich set of symbols, widgets and advanced functions allows the users to do quick modifications.

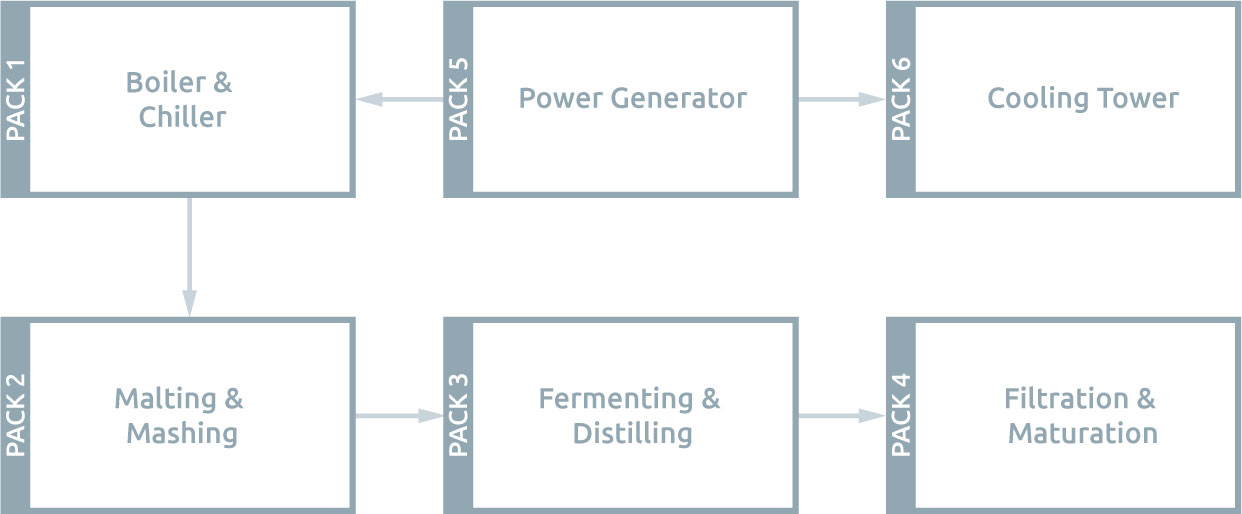

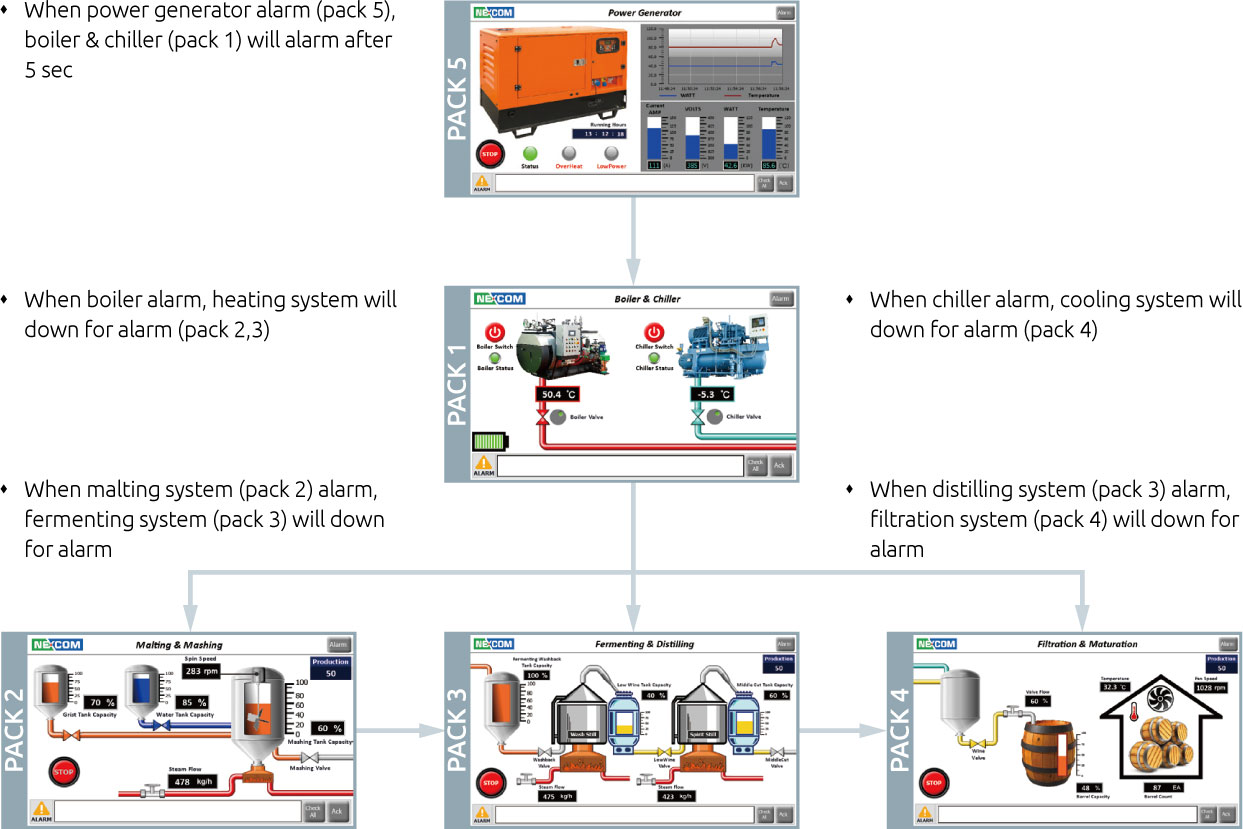

Starter Kit Demonstration: Managing the Process Flow

Starter Kit Demonstration: Interlocking States

OT Devices with Multiple Fieldbus Protocols

iAT2000 starter kit is designed with six independent box, and each box is dedicated with one major fieldbus protocol. (PROFIBUS, PROFINET, Ethernet/IP, EtherCAT, DeviceNET, CANOpen) The starter kit demonstrates the flawless communication crossing different fieldbus protocols and how different process can be interlock with each other.

Independent Pack 1 Configuration

Scenario: Boiler & Chiller

Main Features

- Multi-fieldbus communication

- PC-based controller with CODESYS RTE

- HMI with JMobile runtime included

- Scenario for facility simulation with 4 indicators, 2 push button and 2 knobs

Product Highlight

- NIFE 105W

- Support various fieldbus

- Support discrete I/O module or standard fieldbus module

- Palm size form-factor

- eSMART07N

- Extremely cost efficient HMI

- Slim design. Mounting depth less than 30mm

Independent Pack 4 Configuration

Scenario: Filtration & Maturation

Main Features

- Multi-fieldbus communication

- PC-based controller with CODESYS RTE

- HMI with JMobile runtime included

- Scenario for whisky process simulation with 4 indicators, 2 push button and 2 knobs

Product Highlight

- NIFE 200

- Support various field bus

- Support Discrete I/O module or standard fieldbus module

- Palm size form-factor

- eLITE610

- Extremely cost efficient HMI

- Slim design. Mounting depth less than 30mm

Independent Pack 2 Configuration

Scenario: Malting & Mashing

Main Features

- Multi-fieldbus communication

- PC-based controller with CODESYS RTE

- HMI with JMobile runtime included

- Scenario for whisky process simulation with 4 indicators, 2 push button and 2 knobs

Product Highlight

- NIFE 105W

- Support various fieldbus

- Support discrete I/O module or standard fieldbus module

- Palm size form-factor

- eSMART07N

- Extremely cost efficient HMI

- Slim design. Mounting depth less than 30mm than 30mm

Independent Pack 5 Configuration

Scenario: Power Generator

Main Features

- Multi-fieldbus communication

- PC-based controller with CODESYS RTE

- HMI with JMobile runtime included

- Scenario for power generator simulation with 4 indicators, 2 push button and 2 knobs

Product Highlight

- NIFE 200

- Support various fieldbus

- upport discrete I/O module or standard fieldbus module

- Support 2.5” SSD/HDD

- eLITE610

- Extremely cost efficient HMI

- Slim design. Mounting depth less than 30mm

Independent Pack 3 Configuration

Scenario: Fermenting & Distilling

Main Features

- Multi-fieldbus communication

- PC-based controller with CODESYS RTE

- HMI with JMobile runtime included

- Scenario for whisky process simulation with 4 indicators, 2 push button and 2 knobs

Product Highlight

- NIFE 105W

- Support various fieldbus

- Support discrete I/O module or standard fieldbus module

- Palm size form-factor

- eLITE610

- Extremely cost efficient HMI

- Slim design. Mounting depth less than 30mm

Independent Pack 6 Configuration

Scenario: Cooling Tower

Main Features

- Multi-fieldbus communication

- PC-based controller with CODESYS RTE

- HMI with JMobile runtime included

- Scenario for power generator simulation with 4 indicators, 2 push button and 2 knobs

Product Highlight

- NIFE 200

- Support various fieldbus

- upport discrete I/O module or standard fieldbus module

- Support 2.5” SSD/HDD

- eLITE610

- Extremely cost efficient HMI

- Slim design. Mounting depth less than 30mm

Web SCADA Configuration

Scenario: Local Factory Process Monitoring

Main Features

- Modbus TCP communication

- Panel PC with SCADA software runtime included

Product Highlight

- IPPC 2160P

- Metal housing with robust aluminum front zero bezel for harsh environment

- 10 points P-Cap multi-touch with zero bezel flush front design

- Dual GbE/2nd display-VGA/Line-out/PS2 KB/MS

- Mounting support: panel/wall/stand/VESA 100mm x 100mm

Cloud SCADA with Edge Server Configuration

Scenario: Cloud Dashboard for Factory Productivity and OEE Rate

Main Features

- Modbus TCP communication

- Custom-made cloud SCADA service to design your decision-making applications in cloud

Product Highlight

- NISE 3700

- Modbus TCP communication

- Support 4th generation Intel® Core™ i7/i5/i3 LGA socket CPU

- PC system with cloud IoT dashboard included

- APPD 2100P

- 10 points P-Cap multi-touch with zero bezel flush front design

- 3 display input interface: analog VGA/DVI-D/DisplayPort

Ordering Information

Product Highlight

-

iAT2000 Starter Kit - Full Package

Please contact IAS sales: sales@nexcom.com.tw1x web SCADA, 1x cloud SCADA, 1x edge server, 6x independent packs and accessories

-

iAT2000 Starter Kit - Lite Package

Please contact IAS sales: sales@nexcom.com.tw1x web SCADA, 1x cloud SCADA, 1x edge server, 2x independent packs and accessories