Customer Result :FFG Smart Machinery &I 4.0 Project

FFG Smart Machinery &I 4.0 Project

Project Begins

2017/6

Project Ends

2019/7

Client's Contact

FFG Vice President 繆武良

NexAIoT Contact

Weihan Wang Send an Email

Background

Fair Friend Group (FFG) is the third-largest machine tool group in the world. The Machine Tool Division covers 37 major brands and provides global service and sales networks.

Feeler was the originator of the FFG Machine Tool Division. The division provides a variety of high-precision processing machines. The product series has developed to include various vertical/horizontal lathes and milling machines, five-axis machining centers, and automated production systems, and whole line equipment, etc. However, FFG’s machine functions and features have gradually become indifferent to the competitors. Therefore, FFG had to face a price war in a highly competitive market, which does not bring more competitive advantages to customers.

The Taiwan government actively promoted smart machinery to become another mega-dollar production line. As the leader of the CNC industry, FFG was willing to take the relevant responsibilities. Consequently, FFG developed a smart manufacturing industry based on Industry 4.0 and upgraded the entire business model from the sales of CNC stand-alone machines to hosting services for CNC equipment.

NexAIoT has accumulated many years of experience in the research and development of industrial communication and motion control. Besides having a deep understanding of motion control, NexAIoT is also a well-known Taiwanese representative manufacturer of machine tool networking, informatization, and intelligent integration. NexAIoT and FFG hit it off immediately. FFG chose to cooperate with NexAIoT on intelligent cooperative machine tool IoT and smart integration and committed to complete the three goals: controller localization, unmanned production process, and information IoT. The project started in June 2017 and completed in July 2019.

Challenges

The overall plan took two years to complete, with an investment of more than 50 million Taiwan dollars in research and development, and encountered the following three challenges:

1. Controller Localization

Taiwan’s Industrial Development Bureau of the Ministry of Economic Affairs expects that the cooperation between NexAIoT and FFG could create a national production controller to replace the long-term monopoly of the controller market by foreign manufacturers. For example, FFG’s original unmanned production line, CNC controllers, and production line general-purpose controllers used Siemens controllers, and robot control used KUKA controllers. In this joint venture, the CNC controller would utilize the controller developed by FFG, and the robot controller and the production line general-purpose controller would use the controller designed by NexAIoT.

2.Unmanned Production Process

The second challenge was to introduce the robot-assisted machine tool to load and unload the machining parts, as well as the peripherals of general-purpose machinery, to assist the delivery of products on the production line. In this project, NexAIoT employed a multi-machine and single-control method, using one controller to control all production line behaviors, which can significantly reduce costs due to fewer demands of workers

3.Information Internet of Things

To achieve the overall networking of production, NexAIoT provided an Industry 4.0-ready and web-based graphic control platform. This system handled the tasks, including customized orders, assignments of work orders from the production line cloud management platform, and work notification of each machine. The processing information on the machine tool was visually displayed on the cloud platform, so that managers could comprehend the current processing progress and machine utilization rate, effectively analyze the production quality and progress of the production line, and provide production history tracking.

Solution System Architecture Description

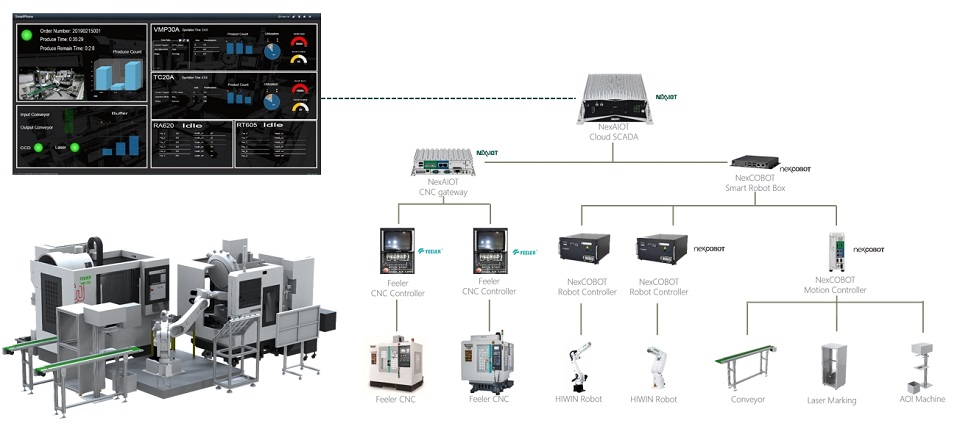

Fair Friend Group provided machine tool controllers, and the IAT2000 system provided by NexAIoT including the combination of CNC Gateway and Cloud SCADA. The robot controller and production line mechanical controller controlled the mechanical peripherals such as automated optical Inspection (AOI), laser engraving machines, conveyors, and then integrated the information with Cloud SCADA through NexAIoT’s Smart Robot Box. At the end, Cloud SCADA is used to connect all equipment controller-related information on the production line to the Internet of Things.

Results and Benefits

The cooperation between NexAIoT and FFG has the following results:

1.Localization of Controller

Fair Friend Group could provide machine tool controllers, and NexAIoT was qualified to supply general-purpose motion controllers and robot controllers.

2.Industrial IoT Module

The industrial Internet of Things module that the two parties cooperated included CNC gateway that could be directly connected to the existing international brand controllers on the market, such as Fanuc, Siemens, Mitsubishi, HEIDENHAIN, and be connected to FFG’s brand of controllers. The Robot Gateway could also be connected with major international manufacturers such as YASKAWA, Fanuc, ABB, and KUKA. Finally, all information could be visualized through the Cloud SCADA production line.

With the cooperation between the two parties, FFG has become able to offer machine tool services with more added value, and operated smoothly in the competition with other machine tool providers in the same industry. By providing machine tool intelligent Internet of Things functions, FFG has won two new contracts. In the face of more competitions in the future, FFG and NexAIoT have signed a strategic alliance to work together to provide more substantial intelligent services. As long as there are similar projects in the future, NexAIoT will act as a specialized supplier for FFG to earn more whole plant and whole line projects of machine tools.