Service Purpose and Goal

NexAIoT's service purpose is to provide overall solutions and be the best partner for smart manufacturing, and to assist companies in achieving the following goals

- Realize industry 3.0-3.3, complete factory automation and production line automation, achieve fewer workers and increase productivity

- Implement industry 3.4-3.5, achieve the digitization of factory production information, and integrate with MES/ERP for management data visualization benefits

- Execute industrial 3.6-3.8, build the intelligent cloud war room, combine big data analysis and AI cloud computing identification, accomplish deep industrial cultivation, and enterprise digital management benefits

Introduction to Planning and Consulting Services

Focus on the current situation of the customer, NexAIoT uses on-site consultant surveys to thoroughly understand the problems encountered by the customer in the transformation, and provide tailor-made, flexible, and suitable solutions. NexAIoT also offers follow-up maintenance personnel training and candidate recommendation, providing a complete turn-key service that achieves the best benefits of smart manufacturing for our customers.

Consultant and Planning

- OT/IT site survey

- I3.0-I3.8 evaluation and recommendations

- Functions and schedules

- Details of the work plan

Old factory I4.0

- Induction of automated production

- Induction of MES/ERP

- Enterprise War Room implementation

- Follow-up service and expansion

Intelligent new factory

- Full digital manufacturing

- Full digital factory equipment monitoring

- Full intelligent enterprise and factory management

- Enterprise MASA/digital enterprise implementation

Complete Digital Factory System Planning Service

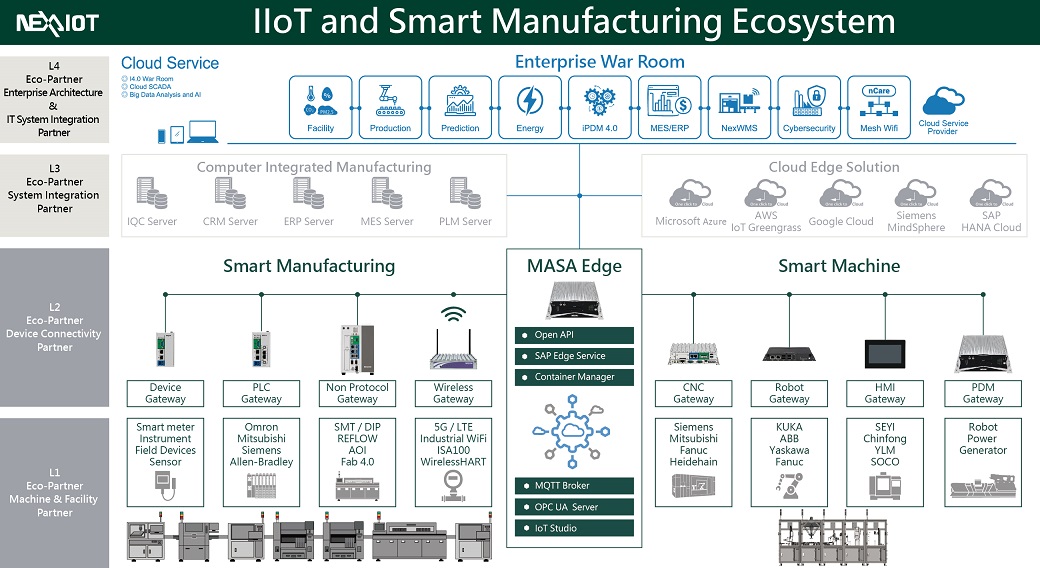

NexAIoT consulting group’s service is based on the system architecture of the smart factory (as shown in the figure below). The consultants will plan from the lowest level. After the completion of the digital enterprise implementation, our customer will be able to comprehend the current production status of the factory, conduct data analysis, and find the niche for the company.

Planning a Digital Factory

NexAIoT's intelligent industrial computers, gateway, and wireless communication products are used to complete factory machine automation, production line automation, and robot automation. These products also provide system integration engineering services to build a highly automated and high-performance manufacturing plant.

Planning OT Middleware Platform

Import the iAT2000 and iRPA2000 system architecture, horizontally connect data collection and automatic control between various devices at the Operation Technology (OT) layer, and then vertically integrate all applications between OT and IT. The platform architecture can be individually targeted at a certain piece to meet specific requirements; it can also be fully expanded into an industrial automation system and merged and integrated with the data level of edge computing and cloud services.

IT Middleware Platform

IT Middleware Platform developed by NexAIoT is built with SAP Edge Server. It connects the data from the digital factory via the iAT2000 Cloud SCADA System, and seamlessly integrates with CRM, ERP, PLM, SCM, WMS, EDA, CIM, MES, QC, SCADA, FMCS, EMS, Production Line Management, and SFC. NexAIoT’s data platform opens up the OT and IT systems, all operating information and data use enterprise architects to import the management methodology. Data analysts are utilized to examine the cause and effect of operation problems through the machine learning platform and construct the machine learning or mathematical models. The data platform predicts potential corporate risks and then ensures the company is profitable with positive numbers to complete digital transformation and borderless smart manufacturing.

Digital Headquarter Building

Enterprise War Room’s various OT/IT management modules and functions use the Mesh Applications Service Architecture to build different microservices that are required for intelligent manufacturing. The management modules store and manage data in the form of data lakes. The data sources include digital twin-structured machines, equipment, assets, systems, management modules, etc. Open RESTful API is used as an interface for open data and functional use among microservices to develop business intelligence applications, such as iService, iSales, and iMarketing.

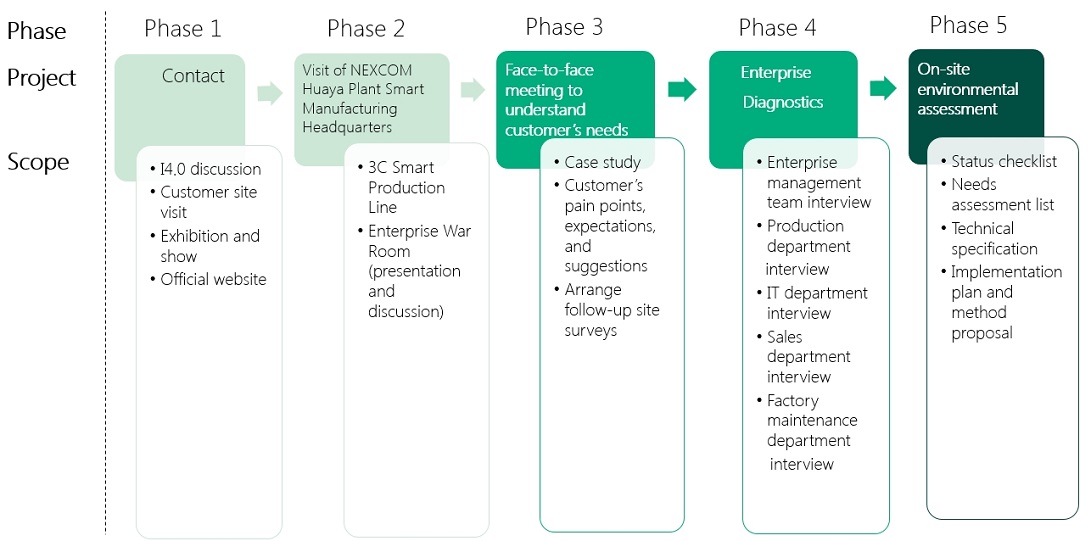

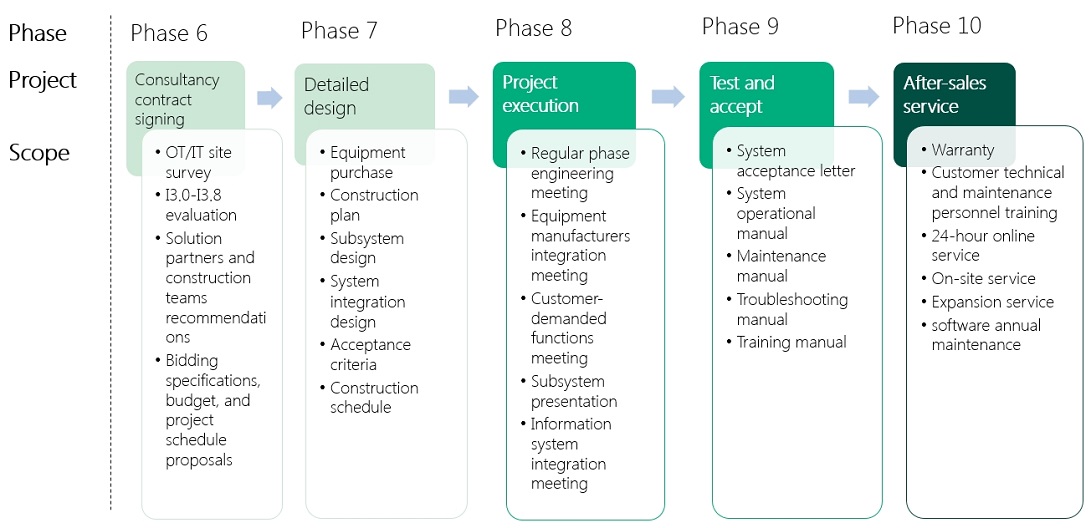

Service Scope & Process

I4.0 Project Team Introduction

The NexAIoT Industry 4.0 consulting team has complete Industry 4.0 expertise and technology and offers robust planning and execution experience to assist customers in achieving smart manufacturing as the mission. Adopting the core technology and value of Industry 4.0, the NexAIoT consulting team upgrades the factory to a full digital monitoring system and empowers managers to make timely decisions through the information in the Enterprise War Room.

Consulting Team

I4.0 Project Execution Team

VP C.C. Lin

Expertise and Qualifications

- Industry 4.0 system solution planning, consulting, and implementation

- Industrial 4.0 solution ecosystem planning and implementation

- Industry 4.0 solution planning, implementation, and training

- 33 years of experience in automation control system technology

Participated Project

iAT2000 Cloud SCADA Division

Eric Lo

Expertise and Qualifications

- Integration planning of non-standard machines/automated control systems and cloud services

- 14 years of experience in industrial control and automation

Participated Project

I4.0 Project Execution Team

Tommy Lin

Expertise and Qualifications

- Factory automation planning and consultation

- Edge computing system implementation

- 8 years of experience in the field of industrial control and automation

Participated Project

I4.0 Project Execution Team

Kevin Tseng

Expertise and Qualifications

- Industry 4.0 system plan planning, consulting, and implementation

- Automation control system/cloud service integration planning and execution

- 20 years of experience in the automation, control engineering, and electrical power fields

Participated Project

I4.0 Project Execution Team

Lenny Chen

Expertise and Qualifications

- Factory automation planning and execution

- Industry 4.0 system program planning and execution

- 10 years of experience in automation product application and project integration implementation

Participated Project

- Gain How Printing I4.0 Smart Factory Evaluation and Integration

- POJU Precision Machinery Intelligent Building Integration

- OptimumNano Smart Factory Project

- Foxconn i8CG Automatic Assembly Line Integration

I4.0 Project Execution Team

SS Lin

Expertise and Qualifications

- 20 years of experience in automation and field automation equipment control

- IoT OT field equipment signal consultation

- 25 years of experience automation planning and implementation

Participated Project

- First Hi-tec Enterprise Co.

- NAFCO

I4.0 Project Execution Team

Rossi Hsaio

Expertise and Qualifications

- Industry 4.0 system plan planning, consulting, and implementation

- Automation equipment integration planning and design execution

- 16 years of experience in automation design and planning execution

Participated Project

- Rovii Robotic Arm Coffee

- Paragon Robotic Loading System & Electronic Display Implementation

- Bionime Corp. Fast Labeling Machine AOI Inspection System

- TEH Industrial Arm Grinding and Building

- AOI Testing equipment Implementation (DIP components)

I4.0 Project Execution Team

Bryan Wu

Expertise and Qualifications

- Industry 4.0 machine networking system integration, program planning, consulting, and implementation

- 4 years of experience in machine networking and war room project planning and implementation

Participated Project