Frequency Components Alliance Industry 4.0 Upgrade Project

Project Name

Frequency Components Alliance Industry 4.0 Upgrade Project

Project Begins

2018

Project Ends

2020/10

NexAIoT Contact

Bryan Wu Send an Email

Background

Frequency components are one of the key components of electronic products. Taiwan’s global market share of frequency components is the second in the world––about 25%––second only to Japan’s 50%––and higher than the third––China’s 12.5%. Among the top 10 industry players in the world, there are four of them from Taiwan.

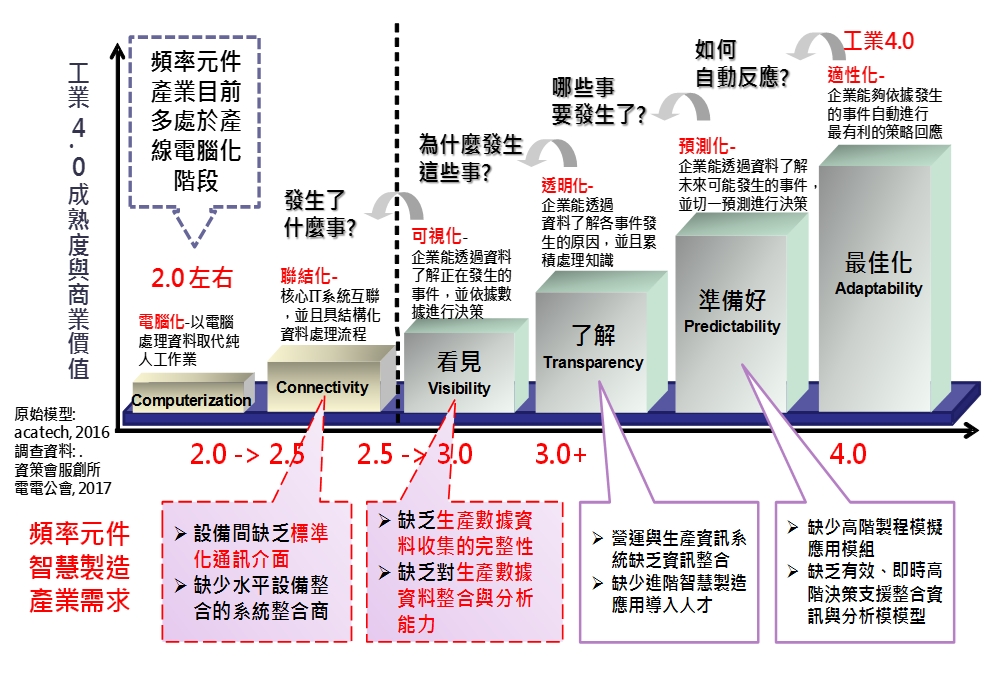

Facing the future market competition, various competitors have invested heavily in intelligent production lines and smart manufacturing applications to improve production efficiency and quality. Therefore, to enhance the competitiveness of the frequency component industry in China, the Taiwan Quartz Crystal Industry Association has formulated a blueprint for the development of frequency components at the end of 2017 to promote the development of the industry 3.0 to above 3.5, focusing on smart equipment and smart production. Industry introduction equipment networking, production information integration, production history, and data analysis applications will be completed from October 2017 to October 2019. And in 2019, the frequency component industry smart manufacturing demonstration team project was launched. The intent was to introduce the common standard communication protocol on the equipment side to increase the proportion of industrial machine networking and result in the improvement of the efficiency of production management. Then, the frequency component industry will gradually move towards Industry 4.0. with strengthened international competitiveness.

NexAIoT won the IoT system integration project in 2017. In addition to importing the iAT2000 cloud intelligent monitoring system, it also commissioned the development of frequency components OPC-UA standard equipment networking modules. TXC Corp., TAITIEN Electronics, and Harmony Electronics Corp. established a demonstration production line to assist the frequency component industry in introducing into the application of smart production and improve the efficiency of small and diverse production.

Challenges

In Taiwan's frequency component manufacturing industry, most of the frequency component production equipment does not have the network function. On-site equipment information acquisition methods tend to be manually copied; thus, makes it is challenging to implement subsequent production management, production history, and data analysis applications. And because the production equipment of frequency components mostly relies on foreign companies, the controllers of different equipment lack standard communication protocols, which is not conducive to the communication between equipment in the future. There are many types of frequency components; different product categories, frequency specifications, and size specifications have increased the production efficiency of a small amount of variety, which has become a problematic bottleneck for the frequency component industry to breakthrough. The data acquisition of the production site also relies on manual reporting, and it is not easy to integrate with the data on the equipment sensors and controllers to develop subsequent production visualization. Therefore, NexAIoT must provide production line information acquisition of the Internet of Things and order information integration, and establish an Enterprise War Room to integrate OT and IT information sharing platform. When the production order status changes, it can immediately respond to improve production efficiency to satisfy customers’ demand for production history.

Solution System Architecture Description

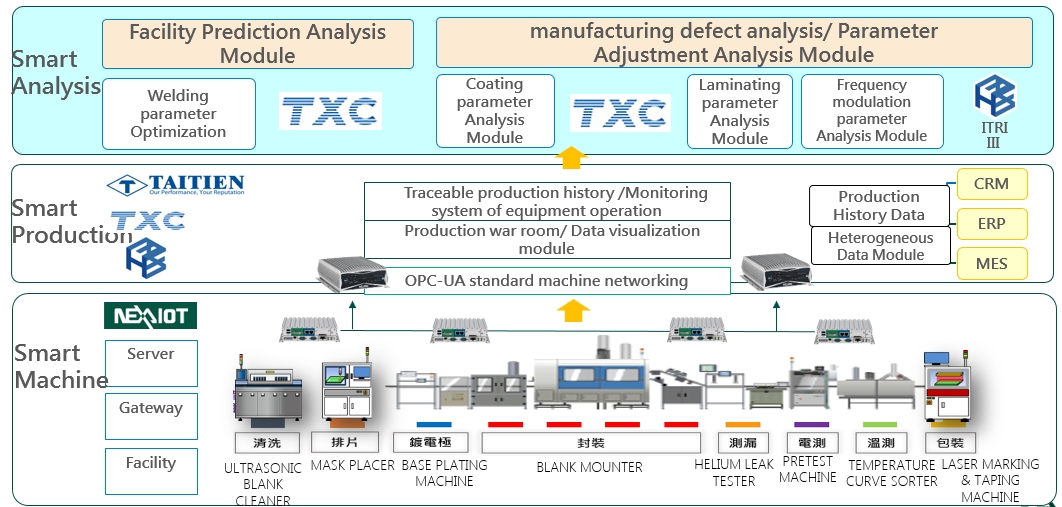

The iAT2000 system by NexAIoT is introduced to solve the problems and fulfill the needs of the frequency component industry. The system uses a gateway to establish a machine network for the frequency component equipment. It employs the OPC-UA communication protocol as the machine equipment network technical framework through the development of OPC-UA edge Server public version to share software and hardware devices. iAT2000 provides a cross-platform communication specification to solve the communication problems between devices of different brands.

The visual war room management technology uses the OPC-UA standard machine networking to integrate data with the MES system and ERP system. The establishment of an electronic monitoring system on the production line allows the business owner to comprehend the production line and equipment status instantly, and the supervisor immediately aware of the work order production status. The traceable production history and monitoring system of equipment operation and plant equipment will improve the efficiency of frequency component production.

Results and Benefits

Combine the R&D application capabilities in industrial communication and system integration, and many years of OT integration experience, NexAIoT focused on industry 4.0 upgrades in various manufacturing industries and provided transparent equipment status and data information to customers.

Visualized Management is adopted for timely predictive management of production information and equipment assets; it improves the reporting efficiency of the process by two times and reduces the false alarm rate. The labor force can be promoted to the production line process management, and the production cycle can be shortened by 30% under the fixed yield benchmark.

It is crucial to have visual system development and equipment M2M integration, frequency component public version creation and employment, and coordination of equipment & frequency component manufacturers to establish an exclusive OPC UA shared version model of frequency components. The future equipment can have a universal communication protocol and effective transmission of instant messages to push the communication protocol of frequency components to international standards and lead the successful transformation of smart manufacturing in Taiwan’s frequency components industry.